Located near Barcelona, here’s a Sustainable Hemp and Medical Marijuana Farm Design by Margot Krasojevic. Catalonia has recently reformed its cannabis law, it has made medical marijuana growth legal and recognized as the next frontier of agricultural growth. Every detail of this building has been designed specially for medicinal cultivation of marijuana, these criteria address three stages of growth. Surrounded by hemp fields since hemp is major contributing building material, the client specifically asked for portable and easily deployable yet sustainable marijuana greenhouse. That three stages of marijuana growth for medical use require to sustain a high TCH level for epilepsy or any other medical conditions such as pain relief, arthritis, multiple sclerosis, and tumour seizures. The area for this farm is perfect to maintain necessary temperature, humidity, and air circulation.

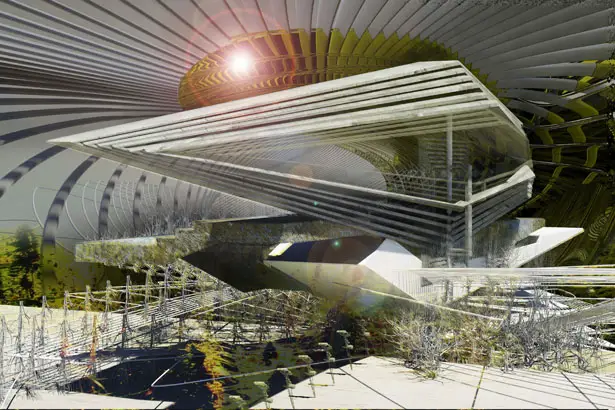

The main cantilevered structure is built using hempcrete. The immediate context is miles of hemp fields, a plant that grows quickly and has been used for thousands of years as part of the building material infrastructure. Hemp is a sustainable material which regulates temperature and humidity, yet when mixed with a lime-based binder it becomes stronger than concrete, this amazing building material is breathable and absorbs carbon from the atmosphere, locking it in, the process of organic hemp to building material petrifies cellulose to strengthen it creating a type of stone stronger than concrete without the need for mixing toxic concrete on site, hemp offers a lightweight yet carbon neutral (negative if insulated correctly) material which is invaluable for a safe sustainable building and site.

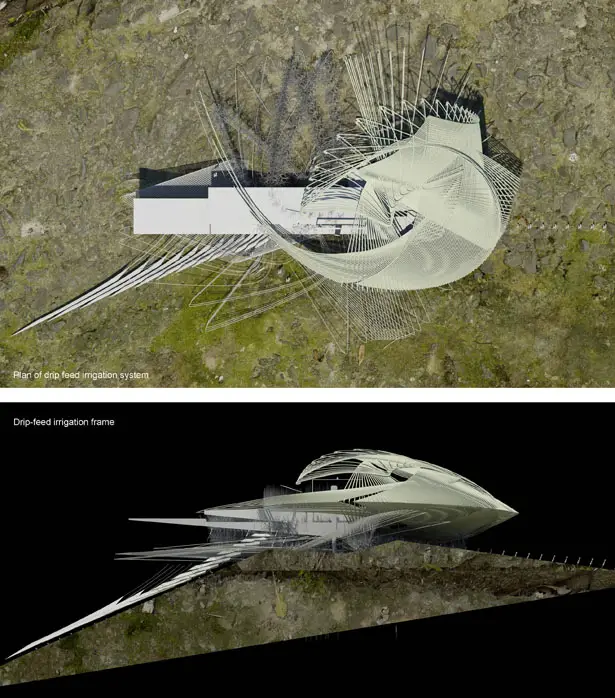

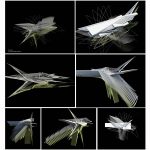

Margot Krasojevic explains that the design of Sustainable Hemp and Medical Marijuana Farm consists of three main areas addressing the three stages of marijuana growth. The main hemp primary structure is a cantilevered frame, the depth of this element contains retractable drip feed irrigation tubes that can be wound in and out of the main structure depending on the size of the external growth fields. The drip feed irrigation uses rainwater which is filtered through the frame through which the necessary nutrients are fed to attain a ph level of 6.5, this sustains a perfect feeding routine from seedling, vegetative stage through to flowering and harvest. This main primary structure contains a deployable inflated structure which provides the perfect climate for the three stages, it is made from ETFE membrane coated hem-plastic, lined with filters intensifying LED’s to aid growth it also is not a complete element as it is inflated in sections creating gaps for natural ventilation depending on the level and pressure of inflation. Air circulation prevents root rot, mold and nutrient burn/light burn. The entire structure needs to be flexible in order for it to breathe with the environment.

The inner section of the primary frame holds a series of rectangular frames which pivot within the primary structure, these frames provide the required pressure for the drip feed irrigation, they need to be flexible in order to cater to the potential harvest which may alter depending on the season. The entire scheme is mobile in order to create the best environment for seedlings and vegetation, once the vegetative stage is over and the flowering stage begins it is set as an automatic feeding frame until harvest, after which it moves to a new location where appropriate.

The building’s primary frame is made from hempcrete that is made on site, it takes approximately 4 months for the hemp to be grown on site after which it is harvested to produce hempcrete, a material that emits no moisture yet sequesters carbon from the environment. Hemp is also used to produce hemp plastic, a bio-plastic sourced from hemp that is not only biodegradable but also recyclable. The filter tinted hemp plastic can be reused and reformed to deploy for the next harvest, hemp plastic is a biodegradable, compostable alternative to petroleum-based plastics, which can feed the farm’s hemp plants once recycled. Hemp plastic starts to bio-degrade after 28 days, after 30 months it is completely reabsorbed into the environment.

The LED lights that are fueled by solar panels can vary from 300nm to a maximum of 800nm depending on the growth stage. An alternative design allows for different yields that have different growth stages to co-exist within the same deployable structure of this Sustainable Hemp and Medical Marijuana Farm but the environments are separate catering to the need of the growth stage accordingly. Using LED lights reduces the watering frequency of the cannabis plants. Rainwater is filtered as it flows through the secondary frame, to which nutrients are added by the time water reaches the plants it is at a perfect PH level needed for each stage of growth.

More images of Sustainable Hemp and Medical Marijuana Farm:

The design’s drip feed irrigation tubes follow paths through and around the building. They also act as a SCROG mesh that controls the marijuana growths exposure to LED and natural light. The flexible irrigation tubes pump water and nutrients to the plants whether they are within the inflatable structure or outdoors when nearing harvest. These gravity fed irrigation tubes are made from hemp plastic and are re-molded on site as necessary, they can also be 3d printed using solar energy. This is a safe way of reproducing and recycling parts for the building’s growth process.

The entire scheme is an environmental drip feed irrigation system that is designed to provide the perfect growth environment for medical marijuana. Sustainable Hemp and Medical Marijuana Farm building materials are sourced on site come from the similar plant as marijuana but without the THC levels needed for medical potency.

Tuvie has received “Sustainable Hemp and Medical Marijuana Farm” project from our ‘Submit A Design‘ feature, where we welcome our readers to submit their design/concept for publication.