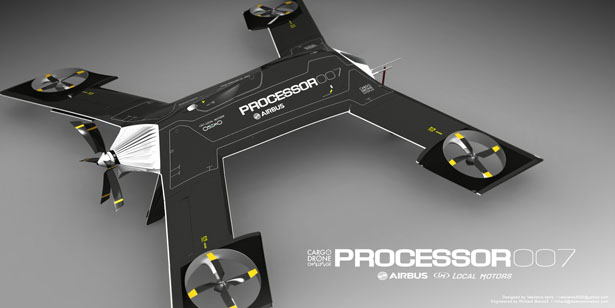

The PROCESSOR 007 is a UAV/drone aircraft design concept for the Airbus Group. It has been designed to perform a series of tasks that could well be the future of emergency delivery systems. It will also prove beneficial to any other delivery tasks required, hence leading to an overall efficiency gain in logistics. Nowadays, cargo delivery or rescue operations are still using outdated systems and in some cases are still carried out by people on foot. Also at present planes and helicopters are usually dispatched from airports, coast guard bases or military bases that can be located far away from the required location, which is very inefficient.

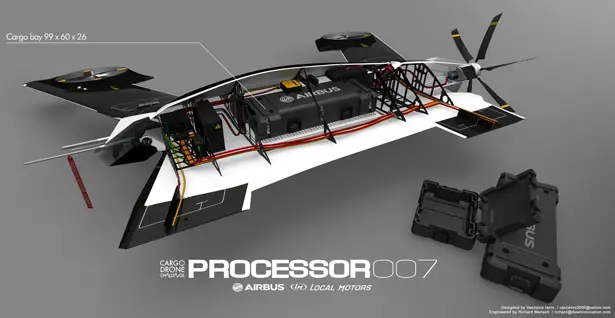

The PROCESSOR 007 has a larger than required payload bay and also features access from either side of the drone to aide loading and unloading. It was designed to be mounted, programmed, loaded with cargo and launched in the minimum time possible with minimum crew. This project aims to spark your imagination around this idea of modularity and efficiency, the exterior body design borrows the line of a wing creating a sleek and elegant shape which is also aerodynamic. The PROCESSOR 007 utilizes hi-tech materials in its construction and it takes minimal storage space thanks to the folding wing design. In the near future it is highly possible you could be witness to seeing this concept become a reality.

Designer : Vasilatos Ianis

Engineer : Richard Mansell

Landing Gear: Landing gear is provided by the four fins on the underside of the fuselage. These are none retractable and are designed to thus also be the vertical stabilizers for the craft. This craft’s rudders are a part of the rear two fins. The lowest end of each landing gear has a place for attaching wheels for optional aircraft-like takeoffs and landings.

Safety Provisions: A number of safety features to both the craft and personnel are provided.

1. For the safety of personnel approaching and around the craft, all the lift propellers are designed to be located completely within the wings. This allows personnel to safely load/unload the payload even while lift propellers might still be spinning down.

2. A complete Flight Termination System involving a parachute and launcher are housed in the top portion of the craft. The Flight Termination Launcher has a proper 45 degree tube and the Flight Termination Parachute has a breakaway cover.

3. Aluminum cooling fins are provided for all motors to keep their temperatures down and minimize overheating of the motors. The fins are strategically aligned with the direction of expected movement while the motors are being used. Thus the Lift Motor’s cooling fins are aligned vertically and the Cruise Motor’s fins are aligned horizontally with forward flight. The Cruise Motor’s fins are designed to contact the Cruise Motor housing within the craft but protrude out of the skin and into the airflow.

4. The provided module that is included to help integrate sensory payloads into the craft’s electronics systems can also provide basic flight control should the craft’s main flight computer malfunction.

More images of Processor 007 Concept Drone Aircraft:

Modularity/shipability: The craft is designed to disassemble into six main parts—none of which are more than 2meters in length. These six parts are the four wings and two fuselage pieces. It should be easy for a single person to carry. Although consideration for the wings folding up against the fuselage is also given, it is considered more of an upgrade option. The Lift Motors are designed to be part of a smaller Lift Motor Assembly that can be easily replaced for quick repairs. These Assemblies are thus swappable.

Sensory Payload: While the payload bay is designed for various types of cargo, provision is made for not only carrying a sensory payload (“Smart Payload”), but a port is provided within the payload bay for integrating the sensory payload into the Flight Computers. This allows for easily synchronizing sensory data with flight information. It also means that the flight computers and the sensory payload can share data resources. For instance the sensory payload could access the craft’s GPS or the flight computer could take advantage of extra data crunching provided by the sensory payload. An module is provided for easily integrating any kind of payload into the craft’s system.

Waterproofness: Batteries and payload openings are provided on the underside which should minimize weather affecting their components even while being loaded/unloaded in unfavorable weather. There are actually no openings on the top of the craft that lead to the inside. The only port available on the top is a waterproof Diagnostics Port. This port is connected to the internal system so that a technician can easily access any of the computer systems without having to open the fuselage.

Tuvie has received this project from our ‘Submit A Design‘ feature, where we welcome our readers to submit their design/concept for publication.